The audio consequences of using wind, rain and virus protection on microphones

Many situations require solutions to protect microphones from the elemental issues. Wind and rain generate noise in microphones. In addition, viruses, like Covid, can be transferred to the surface of a mic. Efficient protection in these cases is necessary, but how these solutions affect audio performance must be understood.

Abstract

Wind: Wind creates unwanted noise in microphones requiring windscreens/shields to mitigate the issues. These practical accessories can control the noise generated under windy conditions (reduction up to 20-30 dB). In general, for these solutions, the bigger, the better. If wind is heavy, a low-frequency cut-off in the recording channel (or the mic) is good protection against driving the input too hard in the LF range.

Rain: Most windscreens can mitigate the issue of rain, at least for some amount of time. However, if the screen gets soaked, it will heavily detriment the sound. For that reason, it is a good idea to bring additional (dry) screens, since thoroughly drying a wet one can take hours. An alternative for rainy weather is using a plastic bag if the job doesn’t entail recording. Be warned though, if the windshield is wet when the plastic bag is placed over it, the humidity around the mic may exceed the limit for proper performance.

Vocal wind: To reduce pops and blows in nearfield voice recording, a pop filter is an effective tool in the studio as it leaves the performance of the mic almost completely unaffected. Usually, the filter can stop the flow at a larger distance compared to a normal wind screen.

Virus protection: Covering a mic with a plastic bag to protect from viral transference is a practical idea. However, it is essential to use a very soft and thin (<10 µm) plastic. In addition, the bag must only be loosely placed around the mic (not packed), or it may change the directivity.

Introduction

High wind and rain generally cause problems during outdoor recording by creating unwanted noise that the mic picks up. In addition, mouth breathing, blows and pops may also create unwanted sounds when close miking vocal performances. Handheld vocal mics can also spread bacteria and viruses.

To prevent unwanted noise generation, it is common to protect the microphones from the weather using windjammers, windshields, windscreens and other specialized solutions. However, not only does the effectiveness of these solutions vary greatly, specific and complete specifications characterizing noise reduction, spectral damping, influence from rain, and so on are seldom given. The missing information is probably in part because of the lack of complete standards in this area.

During the Covid pandemic, using replaceable covers (like plastic bags) to prevent the virus transferring to mic surface, was common practice. While a fantastic solution to keep mics clean, it does affect the sound.

Measuring wind noise

Usually, wind-generated noise is measured in a lab to ensure controlled conditions for the measurements [28]. The standard "IEC 60268-4 Microphones" describes possible "devices" that generate controlled wind (usually a big fan). In addition, the fan must be installed so that only wind noise (not fan/motor noise) is measured. In most cases, this wind machine can produce wind speeds ranging from 0 m/s to >10 m/s.

Typical measurement results include noise spectrum vs. wind speed, equivalent noise level vs. wind speed or equivalent noise level vs. direction. (Equivalent level compares the noise to that generated by an acoustic noise source – how an acoustic source would measure if it generated the same noise as the wind).

If a wind machine is not at hand, natural wind can be used if it can be measured. One low-tech solution (yet possibly less accurate) is to hold the mic out of a car window while driving. The car’s speedometer provides the actual windspeed (10 m/s = 36 km/hour or 22.34 miles/hour).

Wind noise in unprotected microphones

A microphone without extra wind protection accessories is subject to low-frequency fluctuations of the wind. The mic may create, due to its configuration, fluctuations in wind pressure, due to turbulence around itself, even in a steady wind otherwise free from pressure fluctuations. The result may be unwanted audible sound.

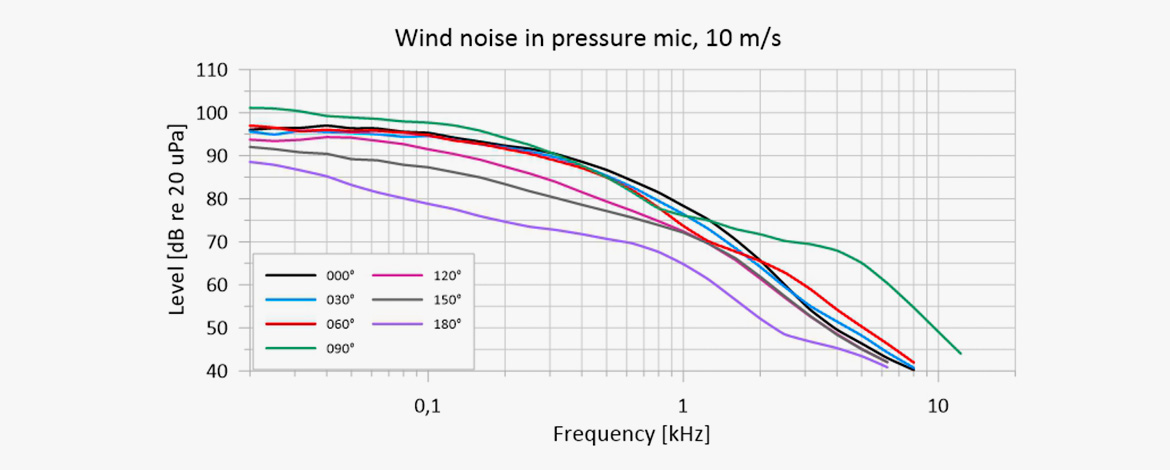

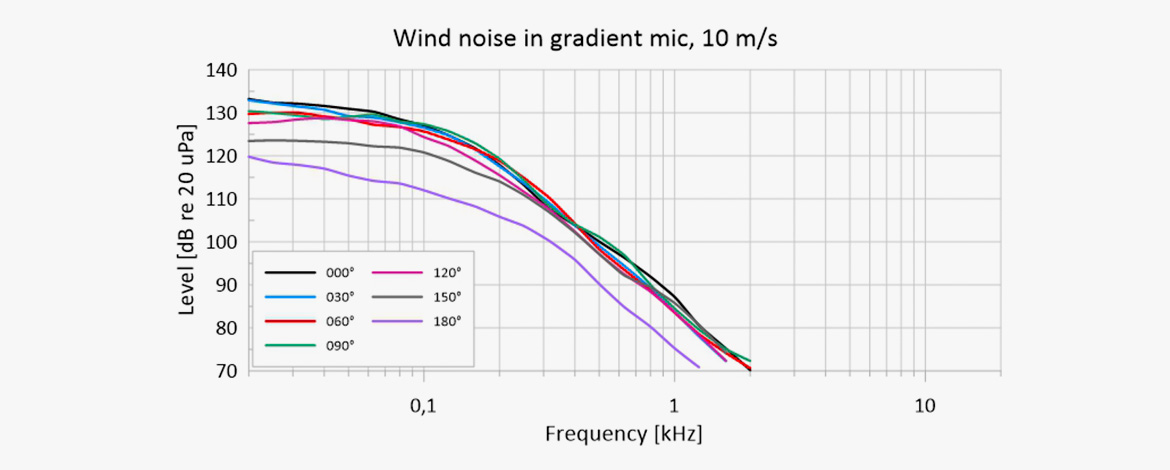

Stronger wind creates more noise. Generally, omnidirectional microphones (pressure microphones) are less sensitive to wind than directional microphones (pressure gradient types). However, the noise level varies with the wind's incidence, even if the mic is omnidirectional to sound. One reason is that the housing and mic shape may influence the level of noise generated.

Below, two diagrams show generated noise vs. direction for a 16 mm omni and a 19 mm cardioid condenser microphone. The noise level difference is around 20-30 dB at low frequencies.

The curves show wind noise vs. direction (30° increment). On both mic types, the noise is highest at 0° incidence (on-axis) and 90 degrees (off-axis) and lowest at 180°.

Fig. 1. The upper diagram shows the wind noise generated in a 4006 Omnidirectional Microphone with 10 m/s wind speed from various directions. The lower diagram shows the noise generated in a 4011 Cardioid Microphone under the same conditions. No matter the wind's angle of incidence, the noise generated is much higher in the cardioid mic compared to the omnidirectional mic (1/3-octave banding).

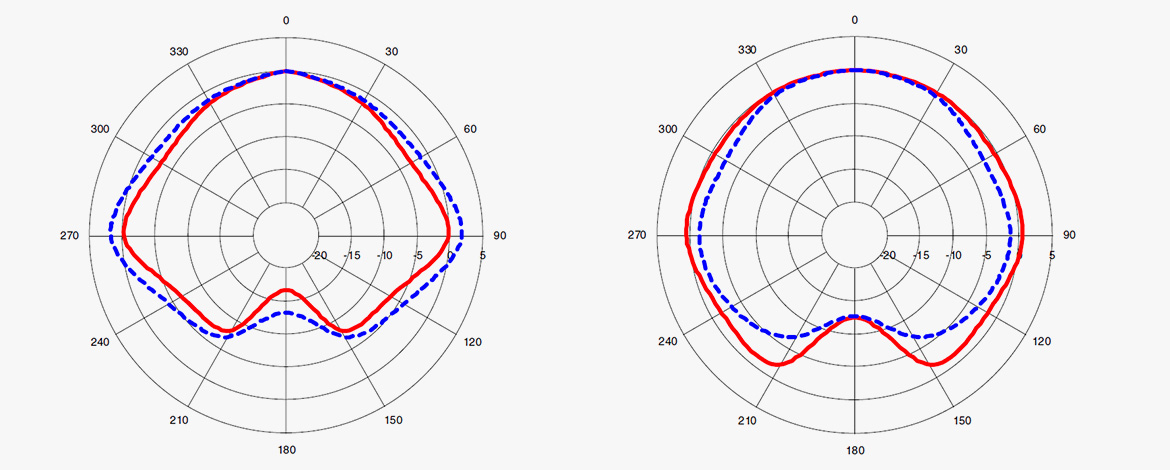

Another way to document the mic's reaction to wind is by creating a polar plot. It is similar to the diagram that shows directivity pattern, sensitivity to sound vs. direction. Below are two charts based on the mic data above, but now measured as an A-weighted and a C-weighted level, respectively vs. the wind's angle of incidence. Both plots are normalized at 0°, meaning absolute noise level is not shown but levelled relative to 0°.

Fig. 2. Now the data is presented as a polar plot. The left diagram shows wind noise generated in an unprotected 4006 Omnidirectional Microphone with 10 m/s wind speed from various directions. The red curve is the A-weighted level vs. direction normalized to 0 dB at 0°. The blue dotted curve is the C-weighted level vs. direction. The right diagram shows the same data in an unprotected 4011 Cardioid Microphone.

The purpose of various wind protection solutions

Wind protection should leave the audio free of noise and free of coloration/spectral damping. Unfortunately, it is difficult to optimize for both simultaneously.

The best protection against wind is a closed rigid box [29]. However, sound will not be able to pass through. On the opposite end, an acoustically transparent device does not stop the wind. The best compromise of these two extremes must be found.

Foam windscreens/shields/jammers

Most windscreens/shields (used interchangeably in the article) are made of an open-cell type of foam that allows for acoustic transparency. The foam can either consist of Polyurethane (PUR) or similar material. Metal foam, with equivalent flow resistance, can also obtain the same result [9]. These windscreens are often circular/ball-shaped, providing the best wind damping from all directions. In general, the larger the diameter of the windshield, the more it reduces wind noise [5, 9, 16, 17, 19]. Omnidirectional mics are not very sensitive to the windshield design as long as the capsule is positioned in the middle. However, cardioid mic performance can suffer if foam covers the front and rear inlet to the diaphragm, which can change the actual directivity of the mic. Some popular windscreens leave airspace close to these inlets to retain the directionality [29].

Shell/basket windscreens/shields/jammers

Shell-type windscreens (often called basket-types) aim to stop wind as far from the diaphragm as possible. They often don’t add any absorption or damping material between the shell and the microphone. The shell/basket consists of a rigid grid covered with one or more layers of fine mesh. Also here, the ball shape is the most efficient, however it is possible to change the form factor (for long microphones) by expanding the ball, or rather, by inserting a cylinder [29].

Fig. 3. Principle of expanding the ball shape.

This kind of windshield is also known by the nickname "Zeppelin" due to its shape, which resembles an airship. They are also known as a blimp in the film industry.

The wind damping of the shell can be improved by adding a foam shield inside before mounting or by adding a fur-like coat on the outside (nicknames: "dead cat" or "dead wombat"). However, adding the external fur can also reduce acoustic transparency.

It is important that the shell surface does not vibrate in the wind, otherwise it is like adding an acoustic source/vibrating membrane close to the microphone. On the other hand, the inside of a cylinder acts as a tube, and standing waves in the enclosure may affect the system's frequency response, according to unpublished findings by DPA.

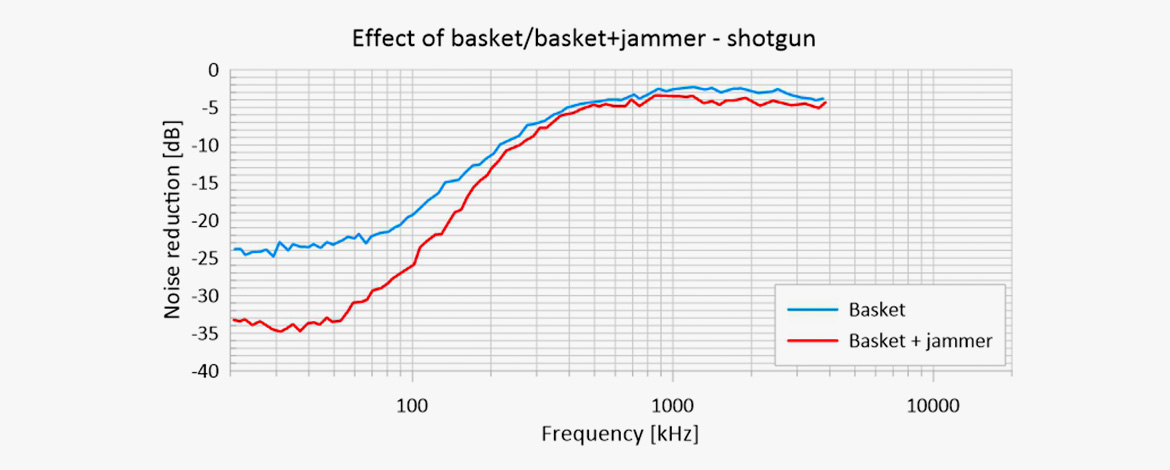

Fig. 4 below, shows the wind damping of a conventional shell/basket-type screen from Rycote (manufacturers data). Here, natural wind was used for the measurements, averaging 20 individual measurements. The microphone is a shotgun type.

Fig. 4. Damping curves for Rycote standard basket + fur-type windjammer. Means of 20 readings (manufacturers data).

For larger microphone arrays (an arrangement of several microphones for a specific setup), creating one basket to cover all microphones can be advantageous, though bulky, construction.

Miniature microphones may also use foam or a shell-shaped grid with fur. The same rules apply to all microphone sizes: Stop the wind as far as possible from the diaphragm. However, the purpose of miniature microphones is to leave the smallest footprint possible. Hence, there are limits to the practical size of applicable wind protection.

It is common to use small foam-based windshields, but a more efficient solution is often needed. Here, the shell/fur solution is used.

Figure 5 shows a standard foam shield and the fur-type Air1 shield for miniature mics.

Fig. 5. Foam and fur windshields for miniature mics.

The three curves in Figure 6 show the noise spectrum generated in a 5 mm lavalier microphone (DPA 4061) without any protection, with foam, and with shell/fur shielding (measured at 5 m/s).

Fig. 6. Noise spectra of wind noise at 5 m/s for a 5 mm miniature microphone, naked, with foam shield and with fur shield (Air1). The fur shield is the most effective.

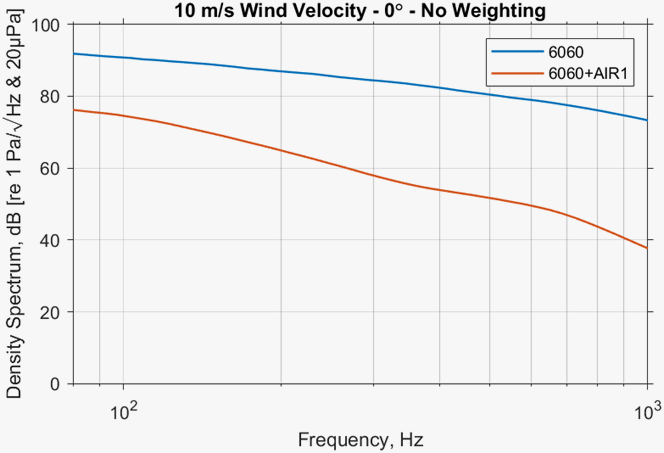

The fur solution also benefits the smallest miniature microphones (3 mm). Figure 7 shows the result of applying an Air1 to a DPA 6060 lavalier microphone.

Fig. 7. Spectra of wind generated noise at wind speed of 10 m/s without and with fur-based shield (Air1). The reduction of noise is approximately 27 dB(A).

Tagged Products

Most vocal microphones integrate a (smaller) basket-shaped grid. It consists of a rigid grid on the outside, which also provides mechanical protection. On the inside, it may have a thin layer of foam as well as an additional mesh. Fig. 8 shows how the DPA 2028 Vocal Microphone implements these components.

Fig. 8. Grid, foam and mesh, protection of the DPA 2028 handheld vocal microphone.

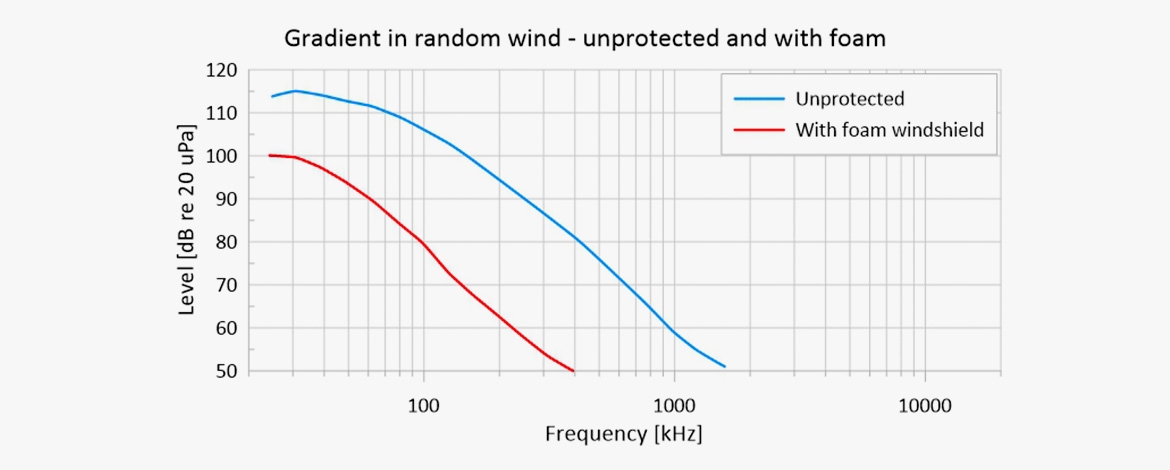

The effect of a foam windscreen, wind noise

The purpose of a windscreen is to reduce the noise created in the microphone, not the sound of the wind itself.

The wind noise predominantly appears in the low-frequency range as long as the microphone (or preamplifier) does not distort. The shape of the windscreen also affects the damping. As mentioned, noise reduction depends on the shield's diameter. So, in this case, bigger is better.

The curves below show the noise spectrum of an unprotected 19 mm pencil cardioid (gradient) mic in a natural wind field and an identical microphone equipped with a 60 mm windscreen. The two microphones are measured simultaneously. The wind speed is in the range of 4-7 m/s. The average time for the analysis is 1 minute. The screen reduces the wind by approximately 15-25 dB in the low-frequency range.

Fig. 9. Noise generated in a 4011 Cardioid Microphone in the natural (4-7 m/s, various directions, 1-minute average). The upper curve: unprotected microphone. Lower curve: microphone fitted with a UA0896 Foam Windscreen for Pencil Microphone, Ø19. The noise damping is in the range of 15-25 dB at low frequencies. (1/3-octave banding).

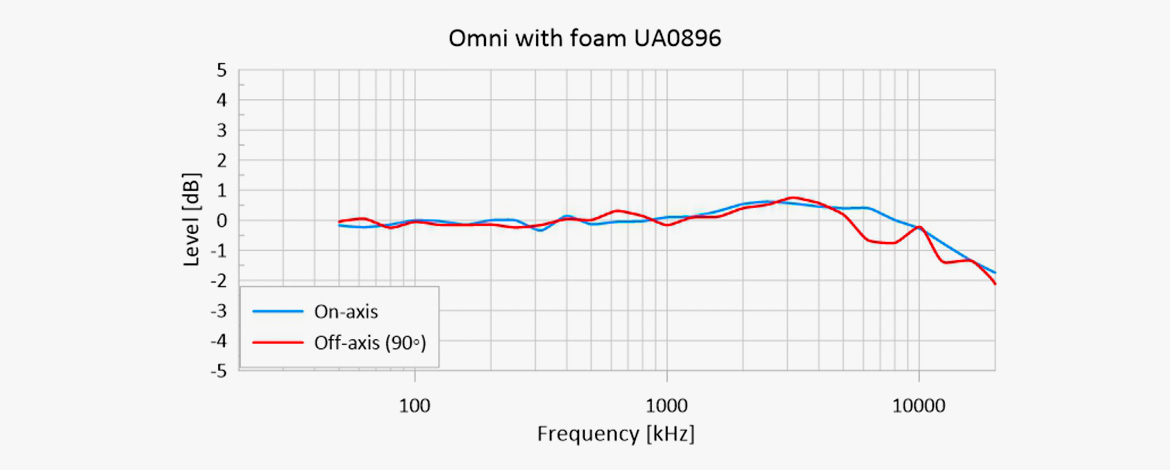

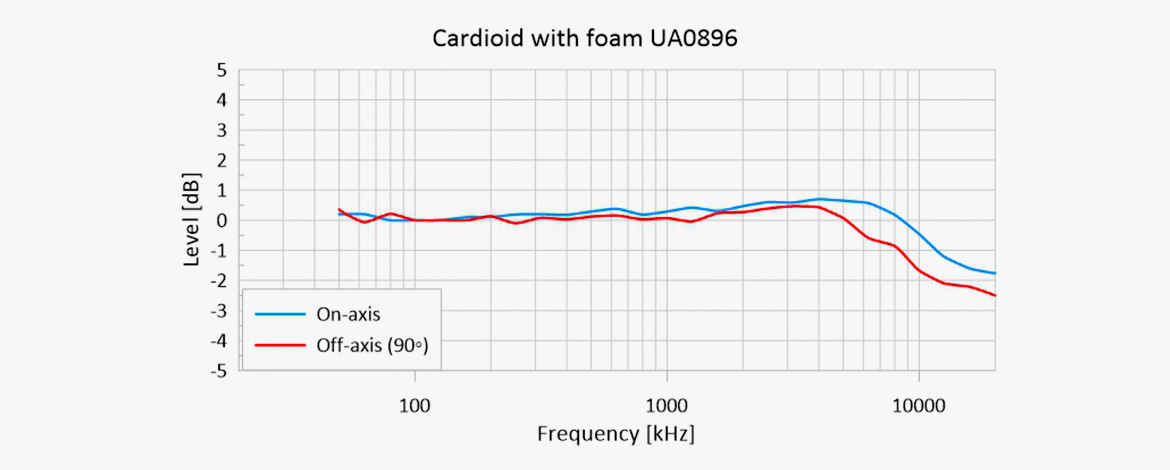

The effect of a windscreen, spectral damping

As mentioned earlier, it is challenging to add wind protection without also introducing some spectral damping. The diagrams below show the windscreen's effect on frequency response. The first chart is an omnidirectional microphone, and the second is a cardioid microphone. The windscreen is the same as demonstrated above: UA0896 Foam Windscreen for Pencil Microphone, Ø19.

Fig. 10. The deviation from a flat frequency response applying a 60 mm foam windscreen. Two mics equipped with a foam shield, measured on-axis (blue curves) and at 90° (red curves). There is a roll-off above 6-8 kHz, with the maximum attenuation being less than 2.5 dB @ 20 kHz. A small gain around 2-4 kHz is negligible. (1/3-octave banding).

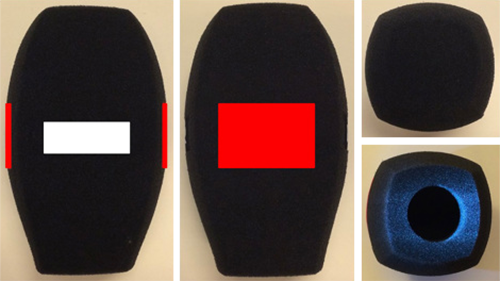

The effect of logos on foam windshields

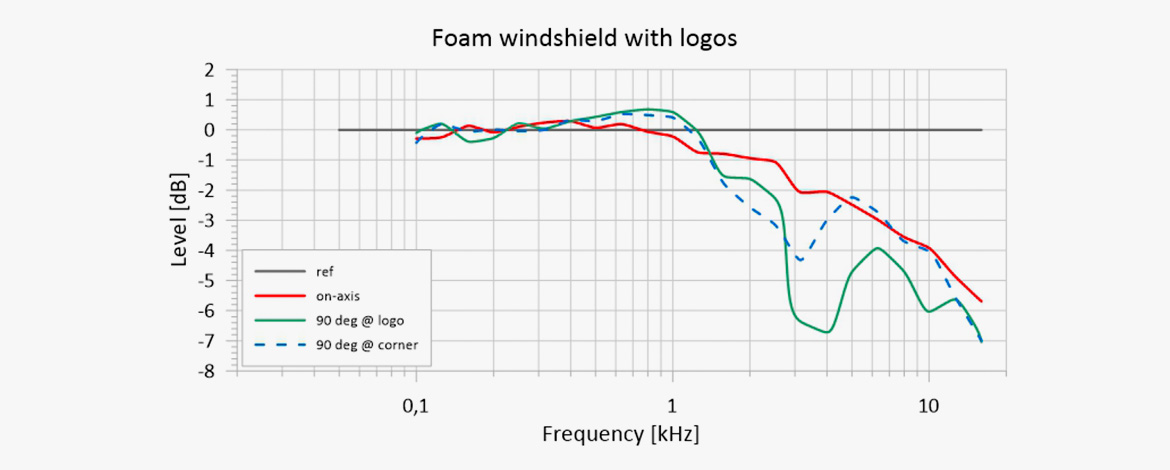

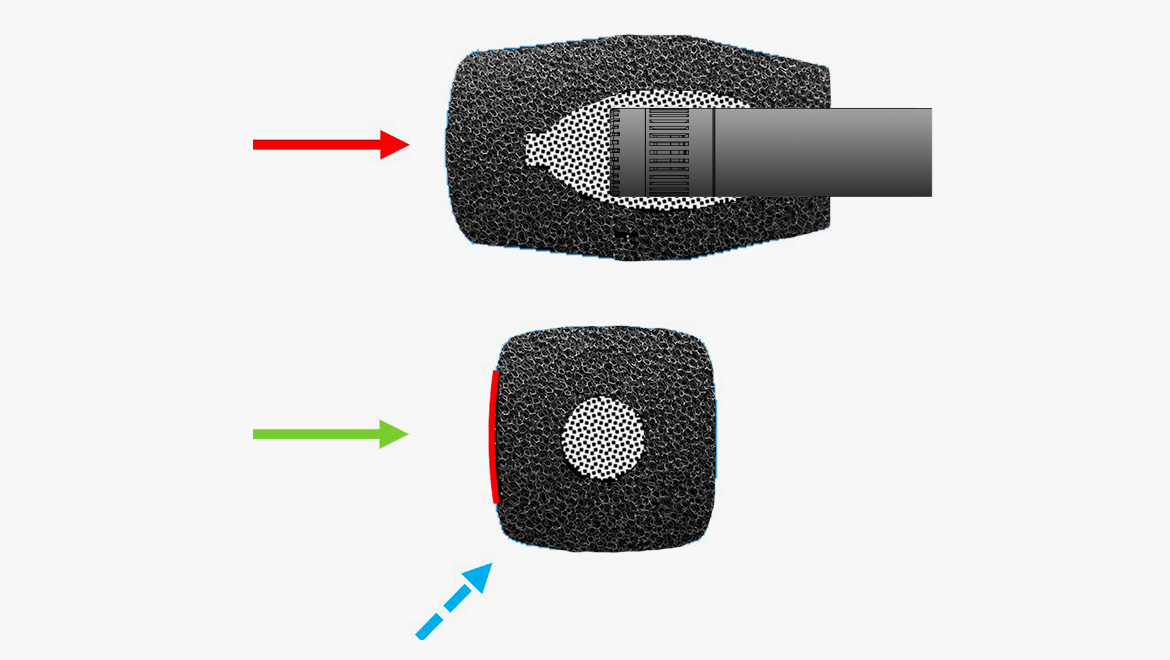

In broadcast, it is common to add logos to windshields. Below is a typical shield with signs glued to the surface. In this case, there are signs on opposite sides.

Fig. 11. Windshield with logos glued on opposite sides.

Below is the windshield's resulting attenuation effect depending on the sound's incidence. When addressed from the top (microphone on-axis), it is an attenuation as expected from the foam. When addressed from the sides, the attenuation is affected by the logos. Unfortunately, the attenuation is increased in the most critical frequency range regarding speech intelligibility.

Pro tip! Don’t address the handheld interview microphone from the side if it is equipped with protection with logos.

Fig. 12. The windshield's attenuating effect is dependent on the sound incident angle. Addressing the microphone from the sides may affect the speech intelligibility due to the additional attenuation in the 2-4 kHz frequency range.

Windshields and rain

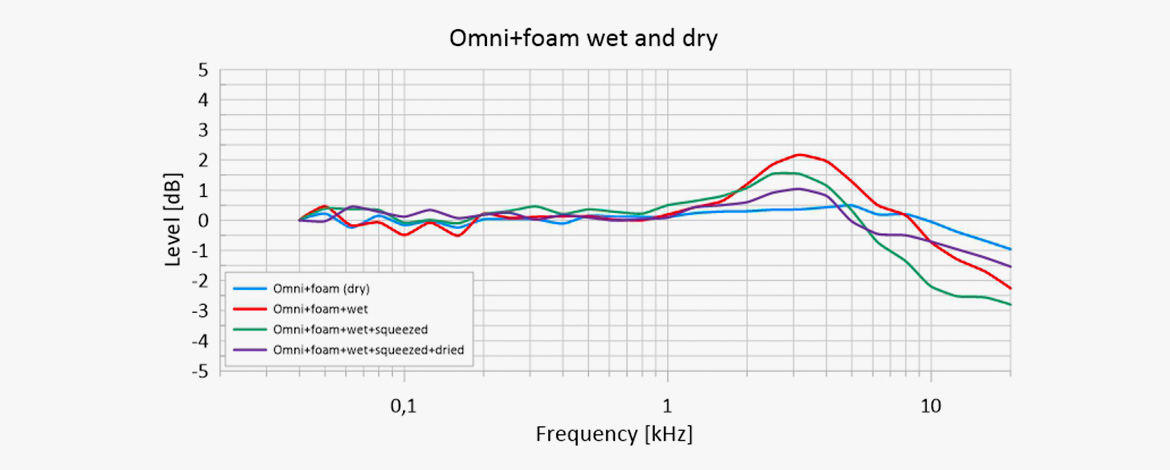

Sometimes, windscreens also must protect against rain. Usually, a few raindrops do not make a difference. Some windscreens have a somewhat water-repellent surface due to a nano coating on the foam. This allows that most of the water runs on the exterior of the screen instead of penetrating inside. This, however, doesn’t work if the foam windscreen is soaked. Microphones are typically not guaranteed to work in humidity above 90%. However, the main problem in this situation is probably not the humidity, but rather the clogging of the open-cell foam.

Fig. 13 below, shows the attenuation of an omnidirectional mic equipped with a foam windshield.

The blue curve (top) shows the attenuation of the windshield when it is unaffected by water. A little attenuation (<1 dB) at 20 kHz is inaudible.

The red curve shows the attenuation when the windshield is soaked. The clogged shield now forms a cavity that exhibits a resonance around 3-4 kHz (almost like "cupping" a vocal microphone).

The green curve shows when the windshield is squeezed out by hand and put back on the microphone. The result is less resonance but more attenuation at higher frequencies >5 kHz,

The purple curve (bottom) shows that after being soaked, squeezed out and dried for an additional half an hour, the screen does still not behave like a completely dry foam screen.

Pro tip! Make sure to bring additional dry foam screens when working in heavy rain.

Fig. 13. The spectral damping of a windscreen 1: Dry. 2: Soaked. 3: Soaked then squeezed out.

4: Soaked, squeezed out and dried for 0.5 hours. (1/3-octave banding).

Special outdoor covers exist, which have a unique ability to let the rain run on the surface and drip off on the bottom, beneath the microphone elements.

Fig. 14. OC5100 Outdoor cover (left) and WJ5100 Fur Windscreen (right) for 5100 Mobile 5.1 Surround Mic (Immersive microphone).

To cover outdoor sporting events, shotgun microphones are often placed around a football or baseball pitch, close to run-lanes, etc. Unfortunately, these events happen in rain and there is nothing to do to protect the microphones as the event continues.

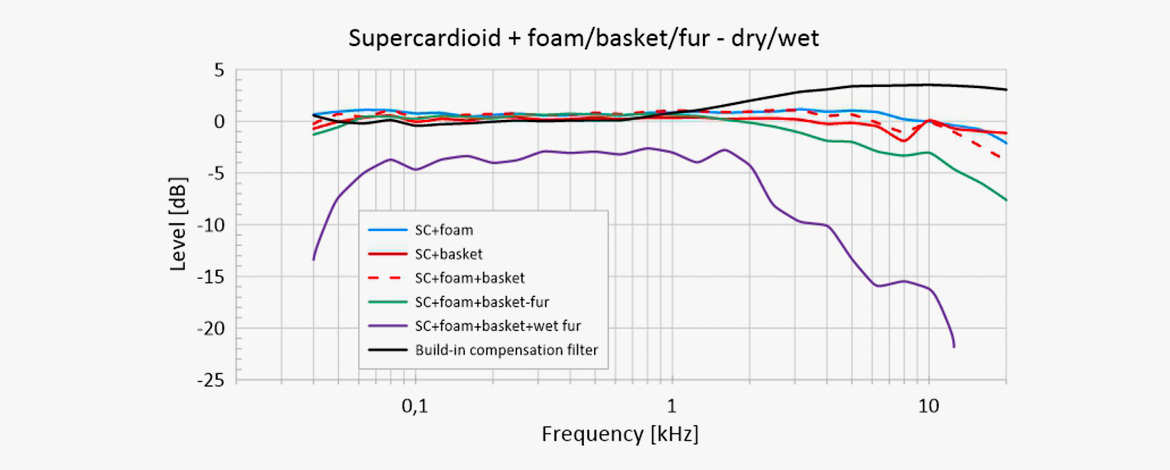

Fig. 15 below, shows sound attenuation by attaching conventional means like foam-, shell-, and fur windscreens for the wind damping. The damping is, of course, audible if all shielding is applied, but it can, by and large, be compensated for. Many shotgun microphones are equipped with a built-in compensation filter. However, if a fur windscreen gets soaked, the attenuation is significant (and is impossible to compensate for).

Fig. 15. The attenuation (on-axis) of sound depends on windshield conditions: 1 (blue): 4017 Shotgun Microphone with foam. 2 (red): 4017 + Rycote basket. 3 (dashed red): 4017 + foam + basket. 4 (green): 4017 + foam + basket + fur. 5 (purple): 4017 + foam + basket + SOAKED fur. Notice the heavy attenuation of the sound. 6 (black): Shows the build-in compensation for the high-frequency loss. However, it is impossible to compensate for the extreme high-frequency damping of a wet fur-coating. (1/3-octave banding).

In rainy weather, a plastic bag can be placed over the top of the foam windscreen. This should only be done before the rain begins to fall, not if the foam is already wet. If the foam is wet, the heat inside the bag may cause the water to evaporate, which then condenses inside the mic. Some mics tend to generate "click" sounds due to this "injected" humidity (unwanted discharging). A better solution is to leave the windscreen and replace it with a dry one when the rain stops.

Pop filter

A pop filter is usually a ring (Ø = 150-200 mm) with one or two layers of cloth (like nylon stockings) or a thin foam disc. It is primarily used for single-person vocal recordings. The pop filter usually has a mounting clamp for the microphone stand. The filter should be placed as close as possible to the speaker's or singer's lips and as far as practically possible from the microphone. Thus, it reduces the airflow as soon as possible before reaching the microphone. As the device only covers one side of the microphone, it does not cause any change of directivity, and the HF-loss is at an absolute minimum.

Fig. 16. Correct placement of pop filter.

Nose cone

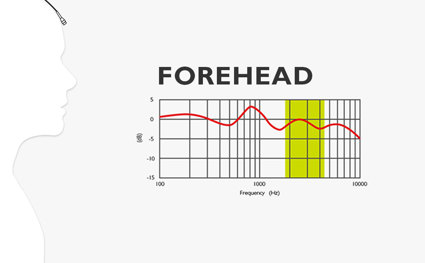

A nose cone replaces the standard grid on a pencil mic and give it a perfect omnidirectional response across the audio frequency range. It counteracts the directional characteristics that omnidirectional microphones exhibit at higher frequencies. It also guarantees an even tonal balance of sound arriving at all angles of incidence but with a high-frequency boost on axis.

Nose cones are efficient for wind noise reduction but only apply on-axis to omnidirectional microphones in strong uni-directional airstreams [9].

Virus protection

During the Covid pandemic, using replaceable covers (like plastic bags) to prevent the virus transferring to mic surface, was common practice. While a fantastic solution to keep mics clean, it does affect the sound. The sound field moves the membrane and sound radiates from the membrane's other side. However, low loss heavily depends on the plastic’s thickness.

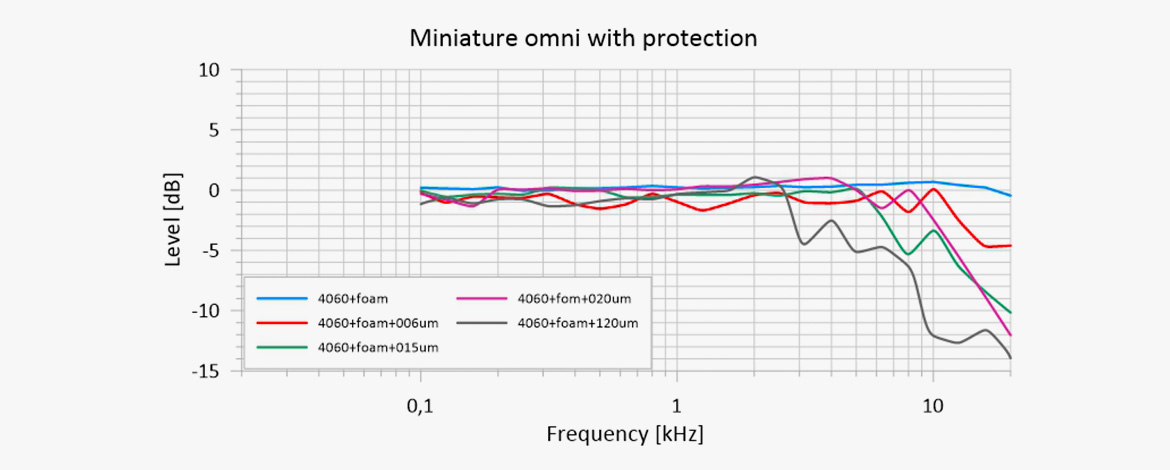

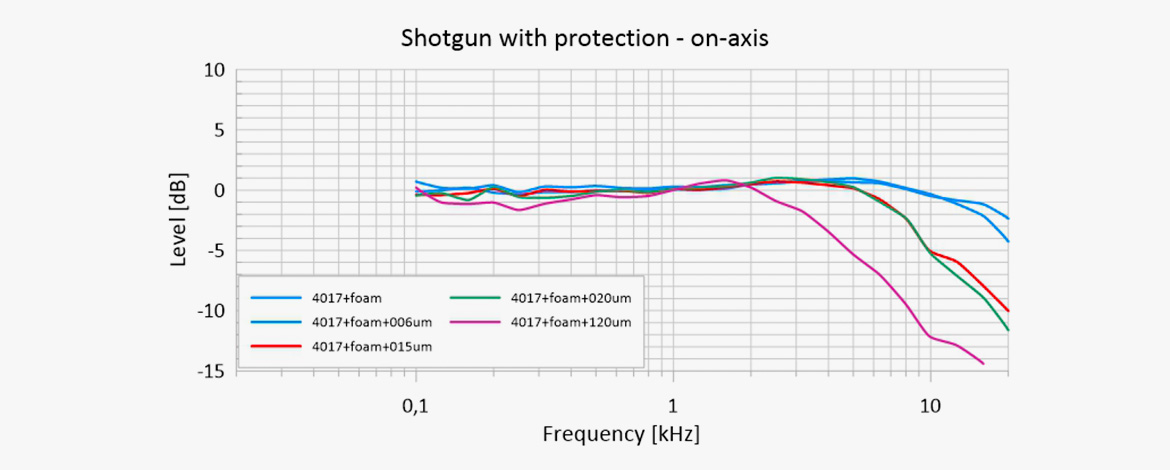

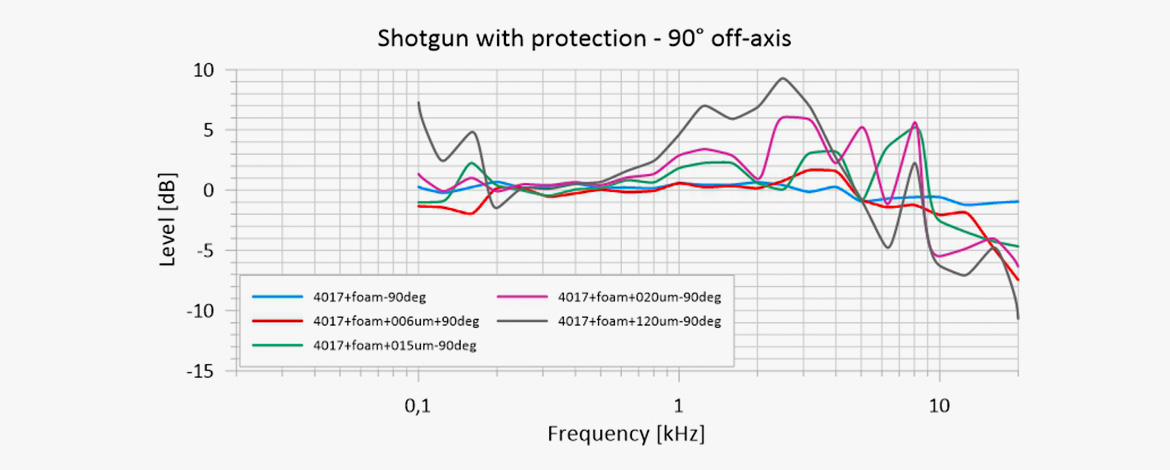

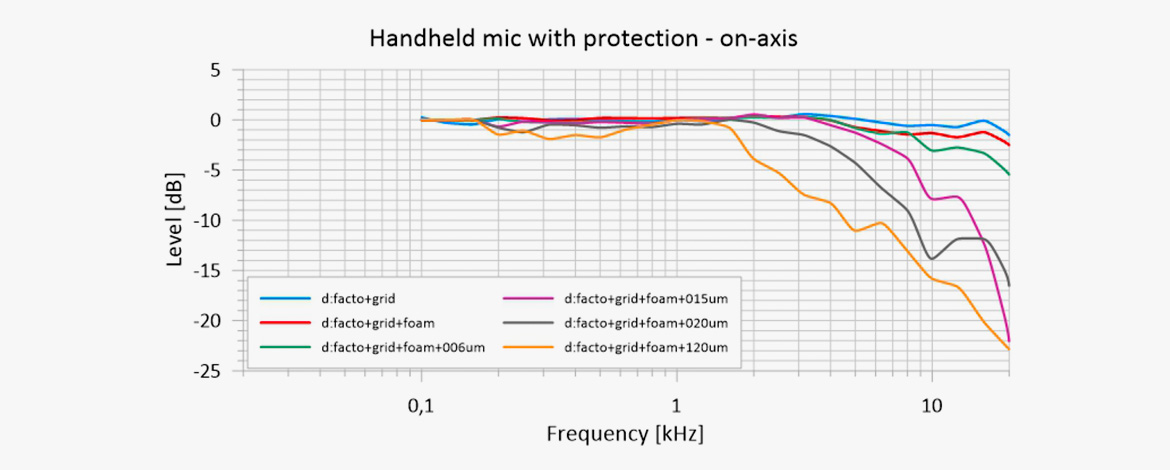

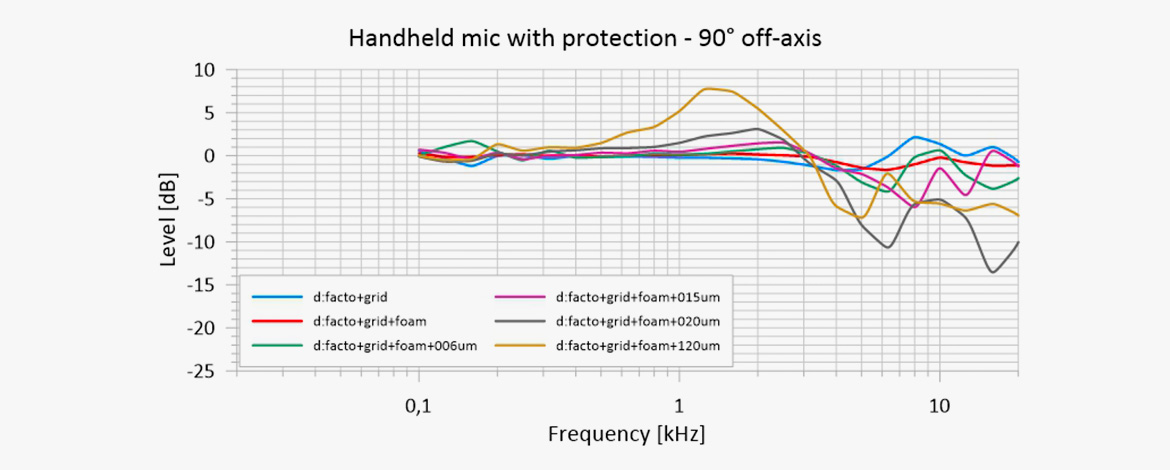

Fig. 17 below, shows the results of a test where three different mics were covered with a plastic bag (one at a time) of various thicknesses: 6 µm, 15 µm, 20 µm, and 120 µm, respectively. The plastic bags were not packed around the mics, but only hung loosely. The bags were also left open. Schoeps experiments [24] indicate that directionality is affected if the plastic layer is packed around the microphone. The figure shows the resulting attenuation and influence on the directional mics. All three mics were equipped with a foam windshield to keep the plastic away from the capsule.

Fig. 17a. The graph presents the results of the measurements of a 4060 Miniature Omnidirectional Mic with a DUA0560 Foam Windscreen and various plastic bags for protection. The results show that the attenuation increases with the thickness of the plastic bag. Even the thinnest bag has an audible, negative influence even though it is acceptable for most purposes. (1/3-octave banding).

Tagged Products

Fig. 17b 1&2. Deviation from the microphones' standard performance: Here are measurements of a 4017 Shotgun Microphone, on-axis and at 90°. The thicker the plastic cover is, the more it affects the frequency response. On-axis high-frequency attenuation occurs. Also, in this case, it reduces the directivity of the microphone (levels are raised in the 1-3 kHz range at 90°). (1/3-octave banding).

Fig. 17c. Deviation from the microphones' standard performance: The d:facto™ Vocal Microphone is measured on-axis and at 90°. Like in 14b, there is a high-frequency loss on-axis and a raise of frequencies in the mid-range, reducing the directivity. However, the effect of the thinnest plastic is still acceptable for most purposes. (1/3-octave banding).

Pro tip! Thin, soft plastic bags (on top of a foam wind shield) can be handy for mic protection. If the plastic is too hard or thick, it may generate noise under windy conditions. Also, if the plastic is too thick, an unacceptable reduction of higher frequencies occurs.

References and literature

[1] Backman, Juha: Numerical Simulation of Microphone Wind Noise, Part 1: External Flow. AES Convention: 134 (May 2013). Paper Number: 8866.

[2] Backman, Juha: Numerical Simulation of Microphone Wind Noise, Part 2: Internal Flow. AES Convention: 135 (October 2013). Paper Number: 8925.

[3] Backman, Juha: Numerical Simulation of Microphone Wind Noise, Part 3: Wind Screens and Shields. AES Convention: 136 (April 2014). Paper Number: 9062.

[4] Becker, Gunnar R., Hermstruewer, Guenther H., and Knoetsch, Rainer: A comparison of conventional and metal foam windscreens. Abstract: J. Acoust. Soc. Am. 117, 2533 (2005).

[5] Bleazey, John C.: Experimental Determination of the Effectiveness of Microphone Wind Screens. JAES, January 1961, Vol. 9, No. 1.

[6] Brixen, Eddy B.; Microphones, High Wind and Rain. AES Convention: 119 (October 2005). Paper number: 6624.

[7] Brixen, Eddy B.; Hensen, Ruben: Wind Generated Noise in Microphones - An Overview - Part I. AES Convention: 120 (May 2006). Paper number: 6635

[8] Brixen, Eddy B.: Wind Generated Noise in Microphones - An Overview - Part II. AES Convention: 121 (October 2006). Paper number: 6879

[9] Brock, M.: Wind and Turbulence Noise of Turbulence Screen, Nose Cone, and Sound Intensity Probe with Wind Screen. Brüel & Kjær Technical Review No. 4. (1986).

[10] Broch, Jens Trampe: Application of B&K Equipment to Acoustic Noise Measurements. 2nd edition 1971, Brüel & Kjær.

[11] Cook, Mylan; Gee, Kent L.; Transtrum, Mark K.; Lympany, Shane V.; Carlton, Matt: Automatic classification and reduction of wind noise in spectral data. JASA Express Letters 1, 063602 (2021); (https://doi.org/10.1121/10.0005308)

[12] Davies, R.A.; Lower, M.C.: Noise measurements in windy conditions. ETSU Report W/13/00386/REP. 1996.

[13] Dillion, Kevin; Raspet, Richard; Webster, Jeremy: Wind noise at a flush microphone in a flat plate. Abstract: J. Acoust. Soc. Am. 117, 2532 (2005).

[14] Hill, Jeffrey; Blotter, Jonathon; Leishman, Timothy: Harsh environment windscreen analysis and design. Abstract: J. Acoust. Soc. Am. 116, 2618 (2004).

[15] IEC 60268: Sound system equipment – Part 4: Microphones. Edition 6 (2018).

[16] Jakobsen, J.; Andersen B.: Wind noise. Measurement of wind generated noise from vegetation and microphone system. Danish Acoustical Institute Report 108. (1983).

[17] Jakobsen, J.: Investigations of wind screens insertion loss and attenuation of wind noise. DELTA Acoustics & Vibration, Note 1, JOR3-CT95-0065, AV50/97.

[18] McIntosh, Jason; Bhunia, Sourav: Wind Noise Measurements and Characterization Around Small Microphone Ports. AES Convention: 139 (October 2015). Paper Number: 9379.

[19] Phelps, W. D.: Microphone wind screening. RCA Review 3 (Radio Corporation of America, New York), pp. 203–212. (1938).

[20] Raspet, Richard; Webster, Jeremy; Dillion, Kevin: Framework for windnoise studies. Abstract: J. Acoust. Soc. Am. 117, 2531 (2005).

[21] Rycote: Wind_Noise_and_Vibration.pdf (rycote.com)

[22] Shams, Qamar A.; Sealey, B. Scott; Zuckerwar, Allan J.; Bott, Laura M.: Infrasonic windscreen. Abstract: J. Acoust. Soc. Am. 114, 2323 (2003).

[23] Shields, F. Douglas: Low-frequency wind noise correlation in microphone arrays, JAES 117, June 2005, pp 3489-3496.

[24] Schoeps: Microphone use & Covid-19 | SCHOEPS Microphones

[25] Wilson. D. Keith: Wind noise and the spectrum of atmospheric turbulence pressure fluctuations. Abstract: J. Acoust. Soc. Am. 113, 2248 (2003).

[26] Woolf, Chris: How to reduce wind noise and vibration. Article at www.rycote.com

[27] Woolf, Chris: Characterization and Measurement of Wind Noise around Microphones. AES Convention 140 (May 2016). Paper Number: 9495.

[28] Wuttke, Jörg: Microphones and Wind. The 91st Convention of the AES, Preprint 3152. (Attention should be paid to the German references mentioned in this paper).

[29] Cook, Mylan; Gee, Kent L.; Transtrum, Mark K.; Lympany, Shane V.; Carlton, Matt: Automatic classification and reduction of wind noise in spectral data. JASA Express Letters 1, 063602 (2021); (https://doi.org/10.1121/10.0005308)